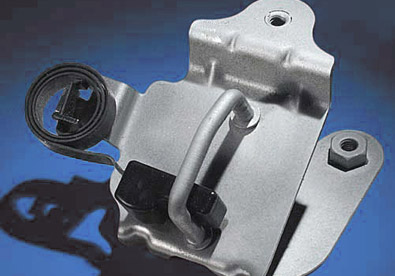

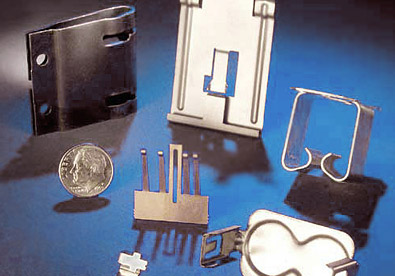

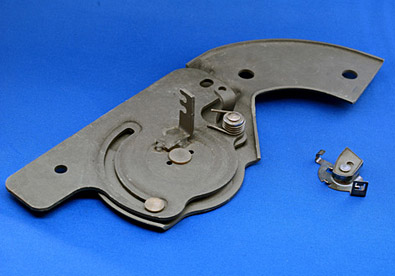

At Active Manufacturing Corp., we specialize in the creation of custom metal prototypes for a broad range of industries and applications. Because most short runs and prototypes act as proof of concept models, we provide a comprehensive set of fabrication processes to ensure highly accurate representations for form studies, functional, and visual validation.

We work with most metals and operate a number of advanced, high-precision CNC machining systems. This includes turning and wire EDM machining as well as hydraulic, servo, and mechanical presses, micro spot welding, robotic laser welding, laser cutting, and much more.

Our highly-skilled machinists are craftsmen and can work with parts as large as 8’ x 4’ and in thicknesses down to 0.002”. As a full-service provider of high-quality prototyping, we also offer assembly, reverse engineering, over molding, several finishing processes, and heat treating. Our specialty production shop can accommodate small manufacturing runs with typical lead times of only three days. In addition, our facility is ISO 9001:2015 certified, ITAR registered, and an approved supplier for the medical industry.

To get your next prototype or short-run project started contact us directly.